|

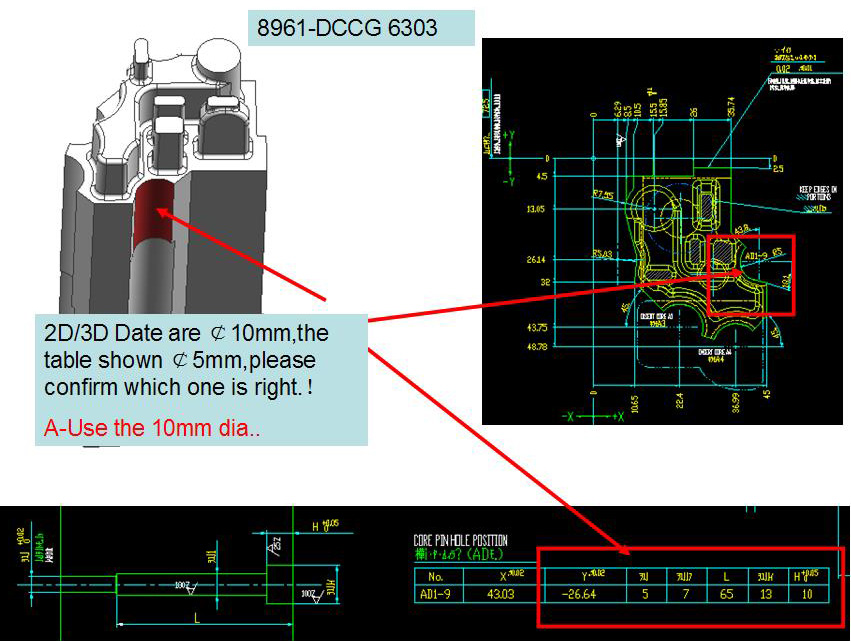

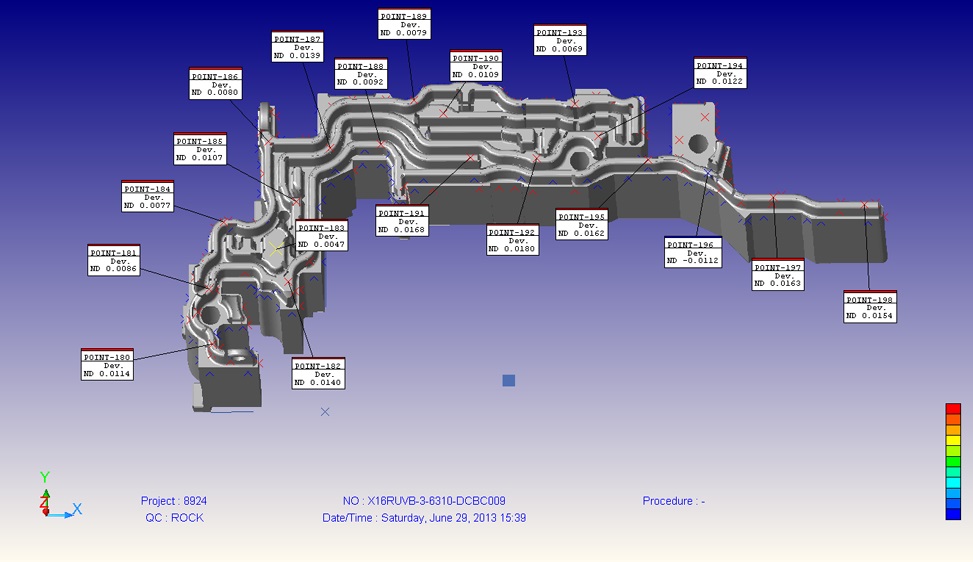

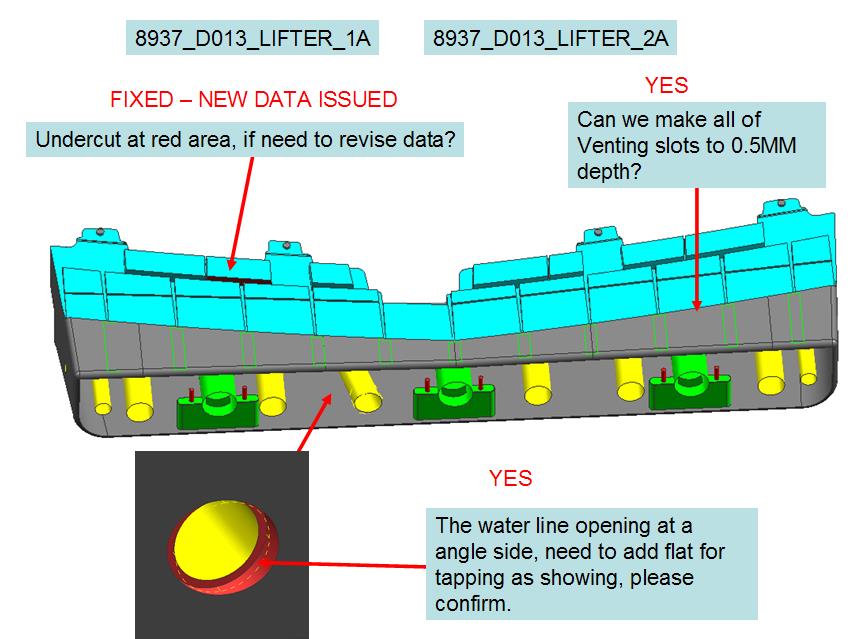

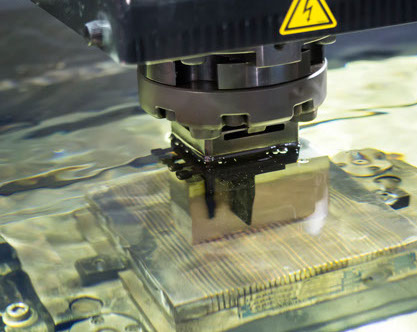

PARTS & COMPONENTS MACHINING —— TIME, QUALITY, PRICE Richen Mould was founded as a machining shop originally and its primary business was parts & components machining in the start-up stage for customers overseas. PARTS & COMPONENTS MACHINING is where the company began and have been growing. As a professional manufacturer of injection mould and parts for over 11 years, Richen Mould has been fully capable of providing highly- quality parts and components for plastic moulds and die-casting tools, with our experienced teams, advanced facilities and outstanding quality control system. We appreciate the opportunity to work for you and your growing business with our expertise and skills. We are here for you with following machining services: 1.Core & Cavity insert 2.Custom Slide & Lifter 3.Spare and replacement parts 4.Other custom parts and components Our standard process:

|

FAQs

Excellent Reputation And Highly Customer Recognition.

- How can I get a quotation and feedback for my products?

- Please kindly send us the drawing of your product. Details below should be included,

A.Materials B. Surface Finish C. Tolerance D. Quantity

(Please be noted that these are essential for our quoting. We couldn’t quote the specific price without any of them.)

- How long can I get the quotation?

- Normally, we can provide instant feedback and then provide quotation within 48 hours(Considering the time difference)

- Are you a manufacturer or a trading company?

- Truly we are a factory. We are a professional manufacturer, located in Shenzhen, China, with over 11 years’ export experience for machining precision parts & components and moulds.

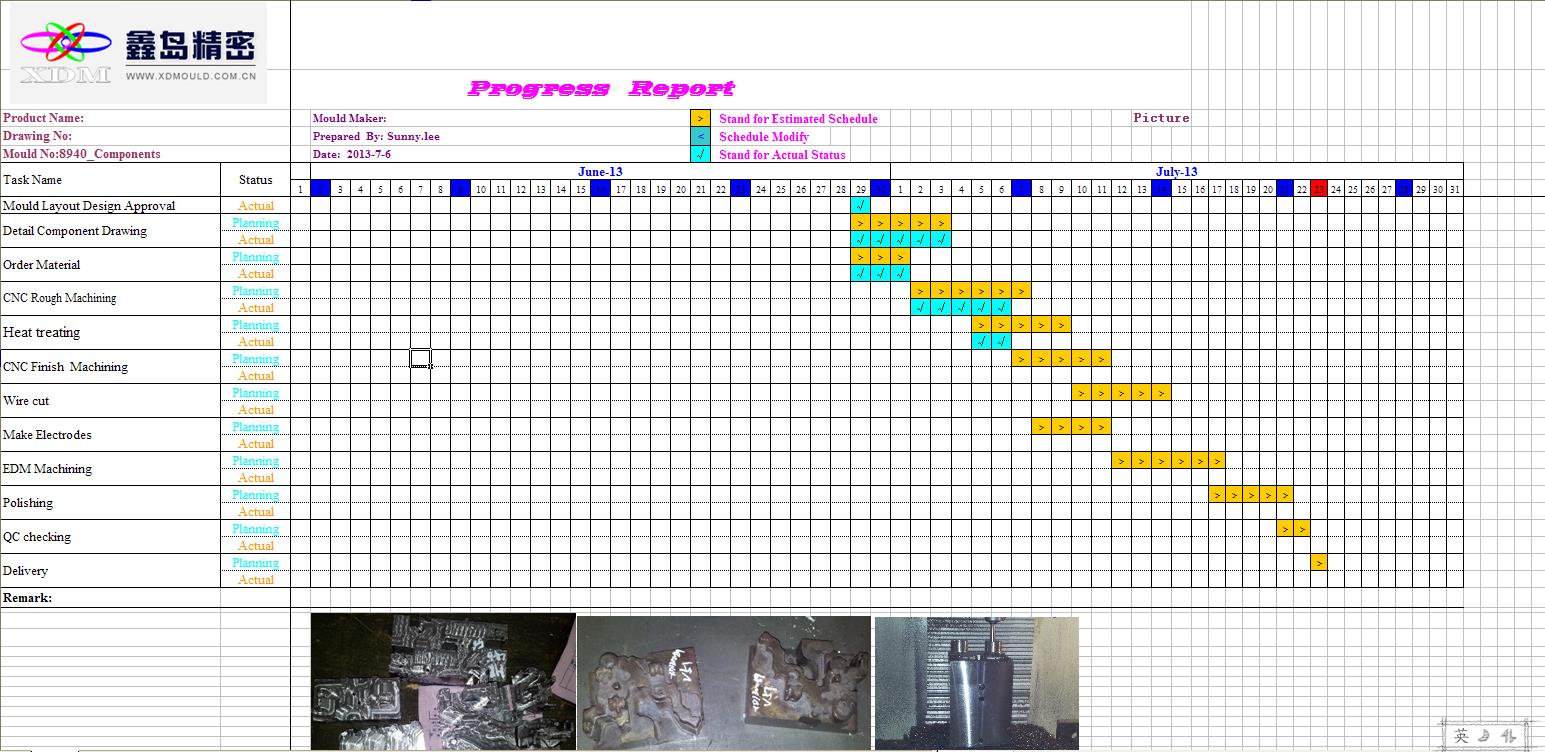

- Is it possible to know how are my products going on without visiting your company?

- Yes. We will offer a detailed production schedule and send weekly reports with digital pictures.

- What’s your MOQ?

- Usually we don't set MOQ, but the more, the cheaper.

- Can you make cnc machining parts according to our drawing?

- Yes, we can make cnc machining parts according to your drawing, 2D drawing, or 3D cad model. If the 3D cad model can be supplied, the development of the tooling can be more efficient. But without 3D, based on 2D drawing we can still make the samples properly.

- What surface finish can you make?

- Zn- Plated,Ni-plated,Passivated,Tin-plated,Sandblast and Anodize, Polish,Electro Painting,Powder coating,Chrome plated, etc.

- What will you do for after sales?

- When our metal parts apply to your products, we will follow up and await your feedback. Any question related to our metal parts, our experienced engineers are ready to help.

HOME

HOME

PRODUCTS

PRODUCTS

SERVICES

SERVICES

CONTACTS

CONTACTS